- Home

- Blog

- About Motor

- What are the types of AC motors? How to choose? Professional manufacturer show you!

What are the types of AC motors? How to choose? Professional manufacturer show you!

Motors are an indispensable part of the automation industry and one of the most common electrical equipment in daily life. They can be divided into DC motors and AC motors according to the type of power supply. AC motors are one of the most widely used type of motor, so how does the AC motor work? What are the types of subdivision? Today, let Kuo Shuay introduce the AC motors that are widely used with simple design and relative low price and strong structure!

What is an AC motor?

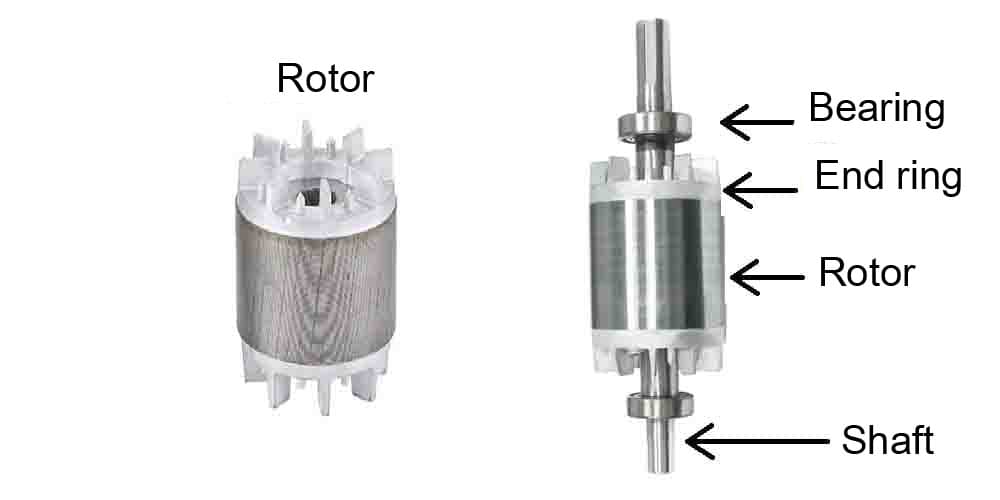

AC motor is a driving device that converts electrical energy into mechanical energy and then into kinetic energy. Because the power supply used is alternating current, it is called an AC motor. The AC motor structure usually consists of a stator and a rotor. The stator is a stationary part when the motor is running, and the rotor spins around the shaft through the bearing. The space between the stator and the rotor is called the air gap, which allows the rotor to rotate without interfering with the stator.

〈Further Reading〉Motor classification

How AC Motors Work?

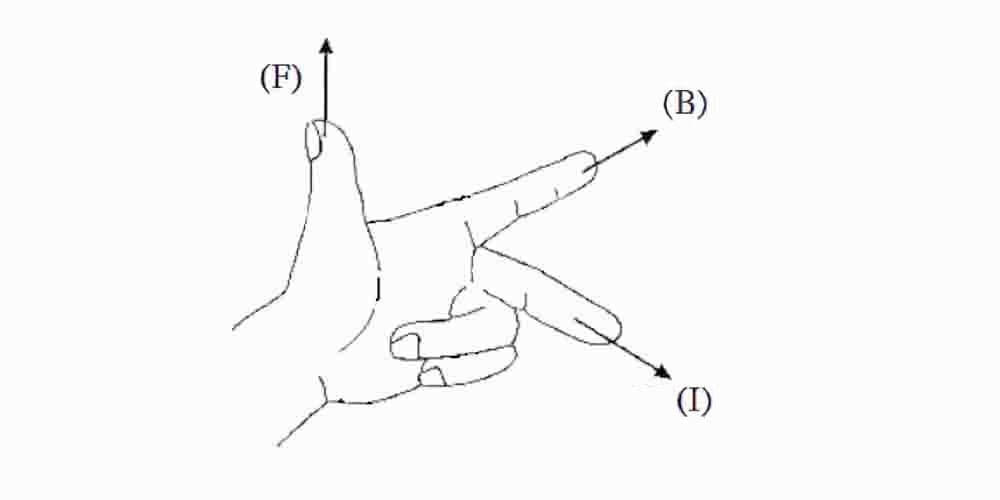

The principle of the operation of the AC motor is through the magnetic effect of the current (the current generates a magnetic field), and the magnetic field is generated according to Fleming's left hand rule. The thumb represents the direction of conductor movement, the index finger represents the direction of the magnetic field, and the middle finger represents the direction of current flow. When the conductor is energized, a new magnetic field will be generated around the conductor, and this magnetic field will push against the original magnetic field to generate a force. The AC motor is composed of a stator and a rotor. Since the stator is fixed, the rotor will move in the direction of the force generated by the interaction.

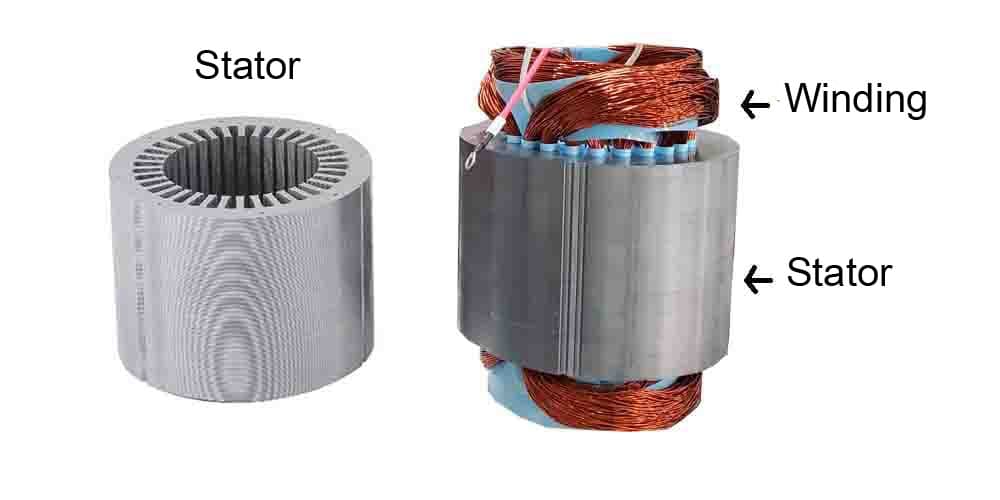

Stator

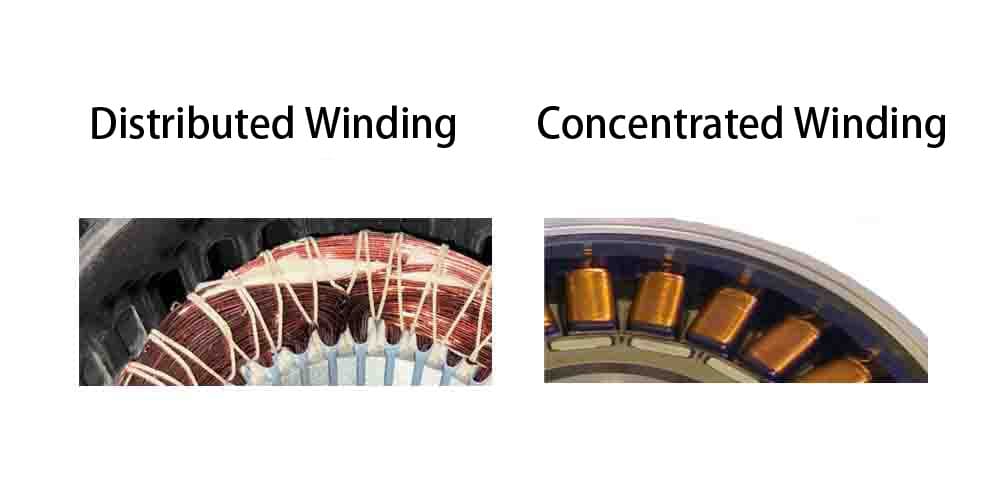

The stator is a fixed unit when the AC motor is running. It is usually composed of an iron core and a copper coil winding. The iron core structure can be made of silicon steel sheets with a thickness of 0.3-0.5mm. The current magnetic effect is generated through the coil winding, and the thrust is generated to further spin the rotor. The stator of a typical AC motor includes a distributed winding stator and a concentrated winding stator. The coils of distributed windings are wound on the iron core according to certain rules and pitches, and different magnetic poles are created after being energized. Most AC motors use stators with distributed windings. Concentrated winding is a rectangular coil that is wound into a convex stator core. This type is more commonly used in DC motors and universal motors.

Rotor

Types of AC Motors

Synchronous motor

Synchronous motor and asynchronous motor (induction motor) both belongs to AC motor. The biggest difference between synchronous and asynchronous is that permanent magnets or electromagnets are added to the rotor. When the motor runs, the rotor rotates at the same speed with the stator magnetic field. The speed of DC motors is changed by voltage, while the speed of synchronous motors is constant. The speed can only be further changed by changing the frequency of the stator magnetic field through the inverter. Considering of motor starting, compared with the stationary rotor, the stator rotating magnetic field speed is too fast. The synchronous motor cannot start by itself, so it needs to be started through damping windings (similar to the principle of induction motor) or reducing the power frequency.

Application:

The so-called synchronous motor in the AC motor, as the name implies, is that the speed is the same as the given power frequency, so the speed is fixed and will not be changed by the load fluctuations. It is suitable for machinery that requires constant speed operation, such as air compressors, grinders, pulverizers etc. A small timepiece, record, tape drive are also the application of synchronous AC motor, uses single phase AC power source to generate a magnetic field. In addition, synchronous motors can also be used to improve line power factor and maintain line voltage stability (Synchronous condenser).

Servo motor

Servomotor generally refers to a motor that can change its action according to commands, so it broadly includes AC motors and DC motors that can be controlled by feedback signals. The servo motor is composed of a sensor, an amplifier and a controller to form a closed loop. First, the sensor detects the rotational position and speed of the motor, and sends the signal back to the controller through the amplifier, and then allows the controller to pass the preset conditions and make judgments. Convert the amplified signal into different control signals to control the motor, and make the corresponding speed and action. The DC servo motor can change the speed through the voltage, and the control is simple, so it is widely used.

Application:

Servo motors in both AC motors and DC motors can perform precise positioning control and speed control. Servo motors are suitable for applications that require certain accuracy for position, torque and speed. Such as cold tandem rolling mills, automatic feeders for metallurgy, wire drawing machines for cables, high-speed braiding machines, extruders for petrochemicals, oil pumping units, spinning machines and fine spinning machines in the textile industry, and wafer processing in the electronics manufacturing industry, laser cutting machine, clean room conveying robotic arm, food packaging sealing machine, plastic molding machine, paper conveying equipment, etc.

Reluctance Motor

How it works:

The reluctance motor is a kind of synchronous motor in the AC motor. It uses the change of rotor reluctance to generate torque to make the motor rotate. The magnetic circuit has the smallest path to move the reluctance to push the rotor, and the stator magnetic field will continue to lead the rotor magnetic pole. Structurally, the stator of this type of AC motor adopts concentrated winding, similar to the structure of DC brush motor. The rotor can be composed of laminated silicon steel sheets, without any windings and expensive permanent magnets, and without temperature and demagnetization restrictions. The disadvantage of the reluctance motor is its torque ripple, which causes vibration and noise. Therefore, the control of the motor circuit is relatively complicated, which makes the application difficult.

Application:

The reluctance motor has the advantages of high efficiency and does not require rare earth materials. Its status in AC motors has been continuously valued and developed in recent years. However, since the reluctance will change with the rotor position, the control is much more complicated than other AC motors. Without proper control, it may cause noise and vibration, therefore, it has not been widely used in the market. Small home appliances such as washing machines and air conditioners are feasible application areas, while reluctance motors for electric vehicles are still in their infancy.

Induction motor

Single phase motor

How it works:

A single phase induction motor is an asynchronous motor, which is a very common type of AC motor, powered by an AC single phase power supply. After current passes through the coil wound around the stator, a rotating magnetic field will be generated in the iron core of the stator, and the rotating magnetic field will pass through the secondary winding of the rotor and will cut the magnetic field with the rotating magnetic field to generate an induced electromotive force. The force generated by the rotational magnetic field on the AC motor stator and the rotor magnetic field cutting each other is the force that drives the rotor to rotate, and this force is generally called torque. Single phase motors produce torques of the same size but opposite directions when stationary, so they need to be started by starting coils, capacitors, etc.

Application:

The single phase induction motor in the AC motor is commonly used in general commercial and household appliances. Because the single-phase AC power supply is easy to obtain, this type of AC motor is widely used. Single phase induction motors are simple and robust in structure, relative cheap and easy to maintain, and can be used in agricultural machinery, medical industry, cement industry, air compressors, cranes, food mixers, industrial machinery, packaging machines, water pumps, refrigerators, air conditioners, washing machines , gate operator, etc.

〈Product link〉Dough Mixer Motor

Three phase motor

The three phase motor and the single phase motor belong to the AC motor, and the operation principle is also very similar. After the three phase AC motor is powered, the current will generate a magnetic field in the stator winding and interact with the induced magnetic field of the rotor, thereby driving the rotor to rotate. Since the rotor is not energized, the magnetic field is "induced" by the stator, so it is also called an induction motor. Different from the single-phase AC motor, the three phase AC motor can generate a rotating magnetic field to drive the rotor to start through the phase difference of 120 degrees of the three-phase power supply, without the need for capacitors, centrifugal switches and other accessories, and the structure is simpler.

Application:

A three phase motor is a type of induction motor and is one of the most commonly used AC motors in industrial equipment. Because the induction motor has a simple structure, does not require permanent magnets, and is easy to obtain materials, it does not require replacement of carbon brushes like DC motors. Therefore, three phase AC motors are used in a wide range of applications, such as MRT traction motors, metallurgical tools, automation equipment, machine tools, water pumps, blowers, treadmills, textile machines, elevators, medical equipment, and electric vehicles. The driving of electric vehicles also uses a three phase AC motor.

〈Product link〉IEC Standard Pump Motor

〈Further reading〉What is an induction motor? An article you can easily understand.

Why choose an induction motor (AC motor)?

Life span

Induction motors are asynchronous AC motors without magnets. Because they do not use magnets, they can operate in a higher temperature environment. People do not worry about high temperature demagnetization and rare earth material acquisition. In addition, because AC motors do not have carbon brushes, there is no need to replace parts regularly. It is very convenient to maintain and only need to lubricate the bearings. Induction motors have been developed for more than a hundred years since the end of the 19th century. They are very stable and mature AC motors, and they are also an indispensable part of industrial society.

Simple structure

There are many types of AC motors. Induction motors have more advantages than servo motors, reluctance motors or synchronous motors in that they are simple and stable structure, easily obtainable materials (no need for rare earth magnets). For AC power of motor, Induction motors account for about 90%, and various industrial applications are very common.

High efficiency

With the regulation of motor energy efficiency in various countries, AC induction motor is the most widely used type. Therefore, in recent years, governments of various countries have set the lowest efficiency regulation for this type of AC motor. IE3 stands for the efficiency standard of induction motors set by the International Electrotechnical Commission, which is equivalent to the Premium efficiency of the United States. The choice of IE3 high-efficiency AC motor can reduce energy consumption and save electricity cost.

Conclusion

Article Classification

Related Articles

- What is an IE3 and IE4 motor? Analysis of Motor Power and Efficiency!

- What is a pole-changing motor? The secret of speed regulation without a frequency converter

- Revealing the secrets of servo motors: types, structures, and application analysis

- What is an induction motor? An article you can easily understand.

- What are the types of AC motors? How to choose? Professional manufacturer show you!