FAQ

- Home

- Faq

- Technical Support

- The most common motor classifications: DC vs. AC

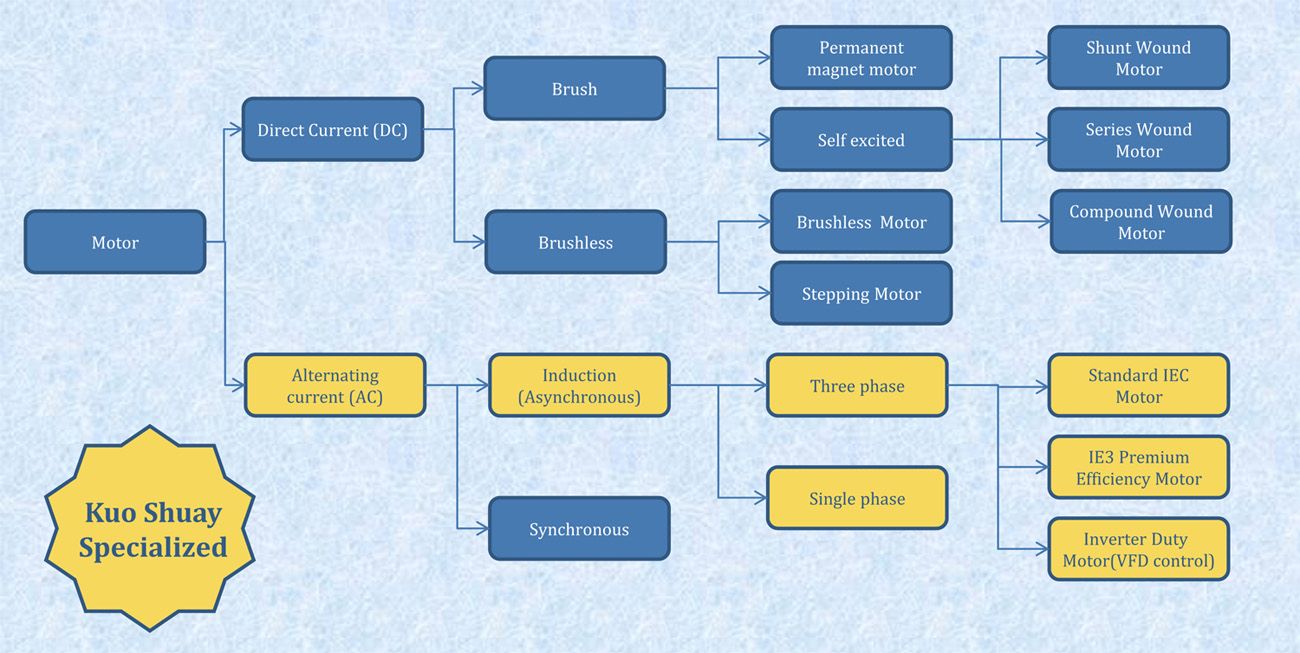

The most common motor classifications: DC vs. AC

The common classification of motors is AC and DC motors. DC motors can be divided into brush DC motors and brushless DC motors. DC motor has good starting characteristics and speed adjusting characteristics. However, with carbon brushes, the armature will wear out which shorten the lifecycle and need replacement. Although brushless DC motors have less maintenance problems, they usually cost more and have limited applications.

AC motors can be divided into synchronous motors and asynchronous motors. Synchronous motors can have smaller size to achieve the same output compare to the asynchronous motor. However, permanent magnet is rare on earths which make the cost rise significantly. Although asynchronous motors may have larger weight and volume under the same power and torque, it is cost effective and easy to maintain compare to other motors.

Asynchronous motors, also known as induction motors, can be subdivided into single-phase and three-phase motors. Because of their high reliability, they are the most widely used motors in various industries and daily life applications.

The following table shows the differences between DC motors and AC motors:

| Differences | DC Motor | AC Motor |

|---|---|---|

| Power Supply | Requires DC power supply | Requires AC power supply |

| Structure | Simple structure, usually consisting of rotor and stator | Complex structure, usually with multiple windings and three-phase power supply |

| Brushes | Uses brushes for commutation | Brushless, as the rotor is driven by induced current |

| Speed Control | Speed can be adjusted by varying the voltage | Speed is usually determined by the supply frequency |

| Control | Speed and direction can be controlled by changing the voltage and polarity | Requires a complex electronic controller to control speed and direction |

It should be noted that the table above only covers the main differences between DC motors and AC motors, and there are other differences such as efficiency, lifespan, and cost. When choosing a motor, specific application needs and requirements should also be taken into consideration.

Selection Criteria

The choice of motor type should depend on specific application requirements. If high precision control and accurate speed regulation are needed, a DC motor may be more suitable. If simple operation and cost-effectiveness are required, an AC motor may be a better fit. Additionally, consider the motor's required torque, speed range, and load characteristics.