- Home

- Blog

- About Motor

- Revealing the secrets of servo motors: types, structures, and application analysis

Revealing the secrets of servo motors: types, structures, and application analysis

What is a Servo Motor?

Servo motor features as its greatly precise operation following the commands by controller and get feedback by the sensor to rotate more precise. Broadly speaking, a simple combination includes a motor, a controller and a sensor, we call it a servo motor. When controller transmits the signal, the motor receives the signal and starts to move, a signal will be sent back to check whether the motor is running correctly by the sensor. If not, the controller will transmit signal to adjust the motor running. It is also the important characteristic of the servo motor.

What is the "servo" of a servo motor?

The working principle of servo motor actually has lots relation with the word "servo". "Servo" comes from the Latin word slave, that is, the motor itself has a master-slave relationship with the controller. The master (controller) commands the slave (motor) to operate, monitoring whether the slave (motor) works according to its own instructions at any time, and can give commands in real time to make the slave (motor) make the correct action.

The structure of the servo motor

Most of the structure of the servo motor is similar to other motors. The difference is that there is an additional encoder, which can send the motor position signal as the feedback to adjust the motor action. The following is a brief introduction to the general servo motors. It can be divided into three parts, controlled device, output device and the feedback system

-

Controlled device:controlled and send the signal to motor

-

Output sensor:check the motor position and send back the signal

-

Feedback system:A closed loop system controlling motor rotation and position.

Types of Servo Motors

Servo motors seem to be simple, but there are actually several classifications. The application and working principle of each type of servo motors are slightly different. They can be classified by DC power supply or AC power supply, or by application method. The following is a brief introduction of different types of servo motors:

DC Servo Motor

This type of servo motor uses DC motor. The coil wound on the central rotor, changing electromagnetic field with make the motor to rotate. Because the direction of the DC current is fixed, the DC motor will be equipped with commutator and brushes to change the current direction. The speed of the DC motor has a linear relationship with the voltage, and the speed can be controlled by the voltage. Due to the characteristic of easy control the DC motor are widely used in servo motor, but it is not suitable for operation in high temperature or flammable environments.

AC servo motor

The AC servo motor adopts an AC motor, and its coil is usually wound on stator. The AC wave will change with time, generating a rotating magnetic field to drive the rotor to rotate. The AC servo motor does not have carbon brush and is easy to maintain. It usually has higher output and suitable for operation in more complicated or harsh environments, but when controlling the speed, it will need inverter to change frequency and then change the speed of the motor.Positional Rotation Servo Motor

Positional rotation servo motors are the most common type of motors. They usually have a structure that stops the rotation physically, so that the rotation of the motor can be stopped at a specified position to avoid excessive rotation errors. This kind of servo motor is commonly used in toy cars, robots and other places.

Continuous Rotation Servo Motor

The continuous rotation servo motor, as the name implies, can be rotated to any direction without limiting a specific stop position. It can also change clockwise or counterclockwise rotation and speed changes, etc., with relatively high flexibility. This type of servo motor often applied to machine that need to move and change direction.

Linear Servo Motor

The linear servo motor is so called tubular linear motor, similar to positional rotation servo motor, except the movement is limited in a straight line. The structure is simple and operated precisely, often use in laser cutting and semiconductor industry.

Advantages and common applications of servo motors

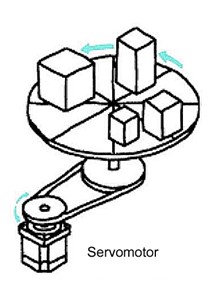

The servo motor can be controlled by detecting the position or speed. For example, the conveyor belt of Amazon logistics needs to classify the package through the position and rotation speed of the turntable. At this time, the motor can not only have the function of rotating, but must drive the turntable to right position at the precise time point. The advantage of servo motor is that it can precisely control the rotation position, so it is also one of the motors that many machines or electrical appliances will use.

- Large machines - precise control of print heads for printing presses, fine weave control for textile machines, and lathe cutting for metalworking applications.

- Robotics - servo motor applications such as walking and movement of robotic pets, and movement control of remote-controlled toys.

- Robotic arm - handling arm, robotic arm.

- Conveyor belt - the conveyor belt can move the produced item to the specified position for the next process, the precise position will need servo motor control.

- Camera - The focus of the camera is driven by a servo motor, which allows the user to adjust the aperture flexibly and smoothly.

Comparison of Servo Motors and Stepper Motors

Automatic control is the trend of modern industry, and both servo motors and stepper motors have the function of motor control, so they are often compared. The stepper motor does not equip with sensor. Therefore, the cost is cheaper than the servo motor. However, the control is not precise as the servo motor. Customer can choose according to the application requirements.

Comparison of Servo Motors and Stepper Motors

| Type of motor | Servo motor | Stepper motor |

|---|---|---|

| Operation | closed loop | open loop |

| Cost | more expensive | less expensive |

| Structure | more complicated | simple |

| Noise | very low | low |

| Accuracy | Less error | More error |

| Time | The estimated path will be different from the actual path, which may take a longer time | No time delay |

| Temperature | Low temperature rise for continuous operation | High temperature rise for continuous operation |

KUO SHUAY Motor

Kuo Shuay is a professional motor manufacturer in Taiwan. Our main products are AC motors, applied to various fields such as air compressor, blower, treadmill, pump, industrial machine, food machine, electric carrier. Current products from 0.01kW to 15kW, we established first UL certified motor Lab in Asia Pacific area. Motor series has been recognized and certified by UL, CE, GB and BMSI. From the sourcing parts and materials to the entire motor, are all strictly controlled by the SOP process. All motors are designed, tested and manufactured in our factory, so that the output motors have more competitive advantages than commercially available motors. If you have AC motor needs, please contact us!

Article Classification

Related Articles

- What is an IE3 and IE4 motor? Analysis of Motor Power and Efficiency!

- What is a pole-changing motor? The secret of speed regulation without a frequency converter

- Revealing the secrets of servo motors: types, structures, and application analysis

- What is an induction motor? An article you can easily understand.

- What are the types of AC motors? How to choose? Professional manufacturer show you!