- Home

- Blog

- About Motor

- What is an IE3 and IE4 motor? Analysis of Motor Power and Efficiency!

What is an IE3 and IE4 motor? Analysis of Motor Power and Efficiency!

When purchasing a motor, choosing a different motor power size is because the motor power directly affects the efficiency and productivity of the equipment. If the motor power is insufficient, the equipment will not be able to operate normally, and if the motor power is too large, it will waste energy and increase operating costs.

A motor generates kinetic energy through electrical energy. When the input electrical energy is fixed, the higher the efficiency of the motor, the less energy it consumes, and the remaining energy can be converted into useful power. Therefore, a high-efficiency motor can produce more output energy while reducing energy waste.

IE3 and IE4 motor refers to a high-efficient electric motor that complies with the latest European electrical efficiency standard. This standard sets the minimum efficiency for motors and requires the efficiency of electric motors to be higher than previous standards. For the same output power, an IE3 or an IE4 motor is more energy-saving than a traditional motor.

What is the motor power and what is the unit?

Motor power refers to the energy produced by a motor when it is in operation. It can also be understood as the work done by the motor in a unit of time.

The international standard unit is usually kilowatt (kW) or watt (W), but horsepower is also used as a unit. 1 horsepower = 746 watts (W).

Reasons for the decrease in motor power during operation

There are many reasons why motor power decreases during operation, including:

- Overloading of motor electricity: Overloading of motor operation will cause a decrease in power.

- Motor failure: Motor failures, such as demagnetization of the magnet or damage to the bearing, will affect the motor's power.

- Voltage fluctuations: Voltage fluctuations will affect the motor's power.

- Temperature factors: High temperature of the motor will affect its power.

- Cable loss: Cable loss will reduce the motor's power.

What problems will occur with too low/too high motor power?

Motor with too low power:

- Insufficient speed: The motor may operate too slowly and not meet the requirements.

- Mechanical damage: Slow operation of the motor can cause mechanical damage.

- High failure rate: Slow operation of the motor can increase the failure rate.

Motor with too high power:

- Mechanical damage: Fast operation of the motor can cause mechanical damage.

- High energy consumption: The use of motors with too much power will increase energy consumption.

- High failure rate: Motors with too much power may cause excessive operation and may increase the failure rate.

How to choose a motor with appropriate power:

- Evaluate the needs: Based on the machine requirements, determine the power required for the motor.

- Machine speed: Compare different motors with different powers to see if they can reach the required speed of the machine.

- Consider motor characteristics: Consider other characteristics of the motor, such as life, efficiency, noise, etc., to ensure the selection of a suitable motor.

What are the reasons for the decrease in motor efficiency?

The deterioration of motor efficiency can be caused by various factors, such as electrical losses, magnetic losses, friction losses, etc. Below is a list of common causes:

- Electrical losses: The losses of the rotor and stator of the motor to electricity will reduce the efficiency of the motor.

- Mechanical losses: The friction and losses between the rotor and stator of the motor will reduce the efficiency of the motor.

- Electromagnetic losses: The losses of the magnetic source and winding of the motor will reduce the efficiency of the motor.

- Temperature factors: High temperature of the motor will affect its efficiency.

- Mechanical imbalance: Imbalance of the motor's rotor will reduce its efficiency.

How is motor efficiency classified?

Classification of motor efficiency

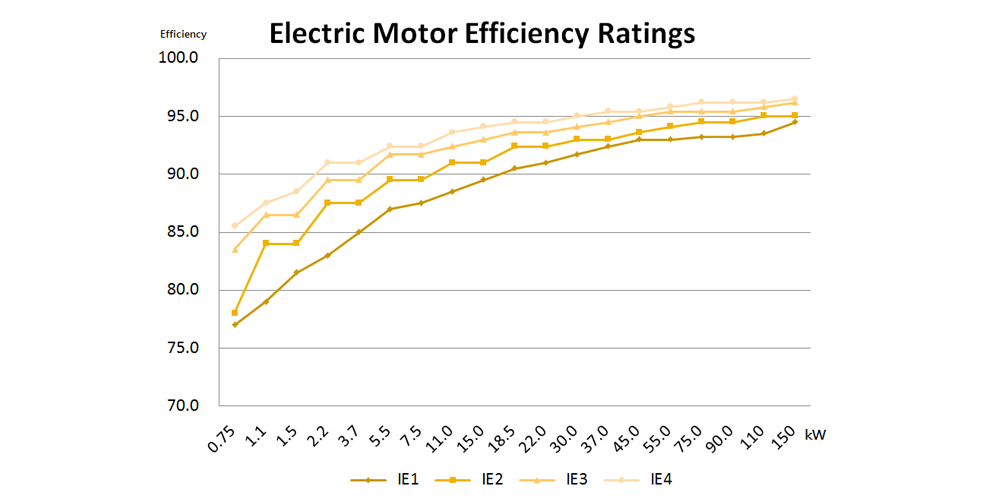

Motor efficiency classification is based on the ratio of the input power to the output power of the motor. Generally, the higher the motor efficiency, the less energy is wasted. According to the IEC standard, the efficiency levels are commonly used to represent motor efficiency, with IE1, IE2, IE3, and IE4 representing different efficiency levels. The larger the number, the higher the efficiency.

Features of IE1 Motors

IE1 motors are the lowest level of international efficiency rating and are also known as "Standard Efficiency" motors. They are manufactured according to the International Energy Efficiency (IEC) standards, which ensure that the motor's efficiency level meets international standards.

Common uses of IE1 motors:

- Infrastructure: IE1 motors are commonly used in various infrastructure systems, such as air conditioning equipment, lighting systems, elevators, etc.

- Industrial Equipment: IE1 motors are also used in industrial equipment, such as robots, production lines, etc.

- Commercial Facilities: IE1 motors are also commonly used in commercial facilities, such as commercial air conditioning, dehumidifiers, etc.

Features of IE2 Motors:

IE2 motors are the intermediate level of international efficiency rating and are also known as "High Efficiency" motors. They are following the regulation of International Energy Efficiency (IEC) standards.

Common uses of IE2 motors:

- Industrial Production: IE2 motors are commonly used in industrial production, such as printing, pharmaceutical production, etc.

- Commercial Facilities: IE2 motors are also used in commercial facilities, such as various fans and wind turbines.

- Public Construction: IE2 motors can also be used in public construction, such as water pumps and water treatment.

IE2 motors are more efficient and consume less power than IE1 motors. Both types of motors often have overlapping applications, and motor selection should consider factors such as cost and efficiency.

Features of IE3 Motor

IE3 motor is a high-level efficiency grade known as the "Premium Efficiency" motor, according to the International Energy Efficiency (IEC) regulations. Many countries and region are asking IE3 as the minimum efficiency when motor import now.

Common uses of IE3 motors:

- Industrial production: IE3 motors are commonly used in industrial production, such as chemical and food production.

- Public construction: IE3 motors can also be used in public construction, such as water pumps and air conditioning systems.

- Environmental protection: IE3 motors are highly valuable in terms of environmental protection and can be used in recycling water systems and environmental facilities.

〈Further Reading〉Kuo Shuay UL Recoginized IE3 Motor

Features of IE4 Motor

IE4 motor refers to the motors that meet the highest efficiency grade (IE4), also known as super-premium efficiency motors. It meets the highest international requirements for motor efficiency. The specifications for IE4 motors are defined by the International Electrotechnical Commission (IEC) in IEC 60034-30-1. Common uses of IE4 motors include industrial equipment, such as pumps, fans and other industrial equipment. They are an ideal choice for equipment that requires long-term operation and high electricity usage due to their high efficiency.

Although IE4 motors are more efficient, they are relatively rare compared to IE3 motors, mainly because they are more difficult to produce and more expensive. However, with rising energy prices and increased environmental awareness, more and more companies are choosing to use this type of motor to save energy consumption and reduce operating costs.

The relationship between IP protection level, poles, speed and efficiency commonly seen on the motor label.

IP protection level is related to dust and water protection and has nothing to do with motor efficiency, but in cases where high environmental requirements are needed, a waterproof motor may be necessary. The number of poles refers to the number of windings inside the motor, which is related to the efficiency of the motor. Usually, the motor with a higher number of poles is more efficient. The rotational speed is also related to the motor efficiency, choosing a motor with a suitable rotational speed can usually achieve better efficiency.

How to Choose a High Efficiency Motor

The following are several factors that must be considered when selecting a motor:- Output power: Choose the appropriate motor power based on the equipment that needs to be driven.

- Speed: Choose the appropriate speed based on the equipment that needs to be driven and product requirements.

- Voltage and frequency: Choose the appropriate motor based on the voltage and frequency requirements of the product.

- Protection level: Choose the appropriate protection level based on the working conditions of the motor.

- Brand and after-sales service: Consider the brand and after-sales service of the motor to ensure long-term stable operation of the equipment.

〈Further Reading〉UL Recognized Preminum Efficiency Motor

Why Choose Kuo Shuay Motor?

The standard for choosing an electric motor usually includes factors such as power, efficiency, size, speed, environmental conditions, etc. When choosing an electric motor, it is important to evaluate it based on specific use requirements, such as whether additional features such as waterproofing and dust-proofing are required, how much power is required, whether cost-saving power and performance customizations are needed etc. Kuo Shuay sells motors for various industries, and with the strong customizability, we can give you the best recommendations and available design.If a high efficiency electric motor is required, the customer may choose an IE3 or IE4 electric motor. Kuo Shuay has a UL-certified efficiency evaluation laboratory and has been in the motor industry for over 35 years. Our high efficiency motor customers include Taiwan's largest semiconductor companies, well-known companies in Korea and Japan, and many retail market in U.S., such as Home depot. The stability and quality of our products are confirmed and recognized. Kuo Shuay can provide comprehensive technical support to customers to ensure that the chosen electric motor meets their specific use requirements and provides full support after motor sold.

〈Product link〉Kuo Shuay IE4 Motor (Super Premium Efficiency)

Article Classification

Related Articles

- What is an IE3 and IE4 motor? Analysis of Motor Power and Efficiency!

- What is a pole-changing motor? The secret of speed regulation without a frequency converter

- Revealing the secrets of servo motors: types, structures, and application analysis

- What is an induction motor? An article you can easily understand.

- What are the types of AC motors? How to choose? Professional manufacturer show you!