ABOUT US

QUALITY CONTROL

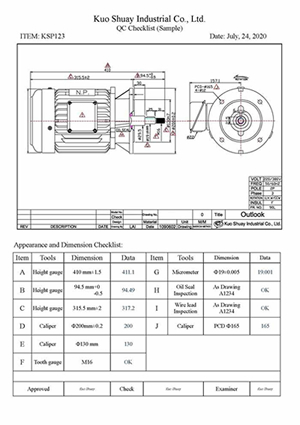

Quality has always been an uncompromising part for KUO SHUAY. Through a strict inspection system, we check and record each process and detail from material to finished product.

IQC (Incoming Quality Control)

- Checking supplier control card.

- Examine each component.

- Sample plan following the Military Standard 105E.

- Key components are 100% checked.

- Measuring equipment are calibrated quarterly by quality control team and calibrated by third party institution annually.

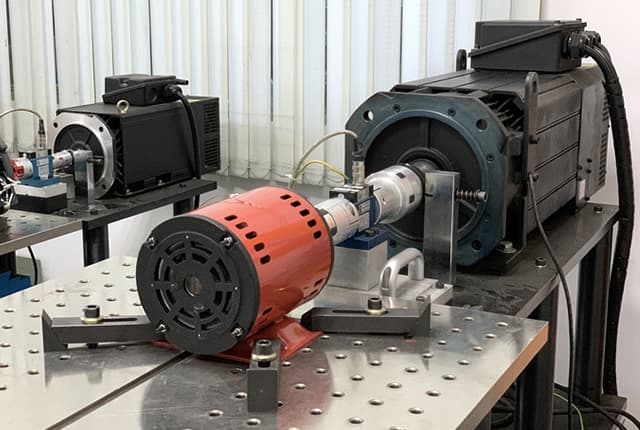

IPQC (In Process Quality Control)

- Patrol Inspection : Check the appearance, assembly tolerance, rotation, operation sound, adjust the machine to accuracy position, and examine the incoming components.

- First Article Inspection : Professional quality control personnel will go to the site to randomly check semi-finished products and finished products to see whether the materials used are the same as the BOM, confirm whether the process is in accordance with SOP, and correct errors and corrections in a timely manner to avoid the generation of a large amount of waste.

OQC (Outgoing Quality Control)

After appearance and label inspection, all motors would stay in noise test room for 100% test before packing. These tests include high potential test, insulation resistance test, layer test and performance test. Each motor has a unique tracking number and could easily follow up in the future.

.jpg)

ISO9001 Certification

Appearance Inspection Sample

〈Further Reading〉 Company Profile - What do we do?

〈Further Reading〉 Services - Are Customizations Available?

〈Further Reading〉 Factory - How Many Production Lines Do We Have?

〈Further Reading〉 Milestones of Kuo Shuay